Ribbon fiber optic cable is a typical fiber optic cable. Unlike beam optical cable, ribbon fiber optic cable is arranged into a strip. Ribbon fiber optic cable is a convenient solution for space and weight problems. The cable ribbons are actually coated optical fibers placed side by side, encapsulated in Mylar tape, similar to a miniature version of wire ribbons used in computer wiring. A single ribbon many contain 4, 8 or 12 optical fibers. There ribbons can be stacked up to 22 high.

Because the ribbon contains only coated optical fibers, this type of cable takes up much less space than individually buffered optical fibers. As a result, ribbon cables are denser than any other cable design. They are ideal for applications where limited space is available, such as in an existing conduit that have very little room left for an additional cable.

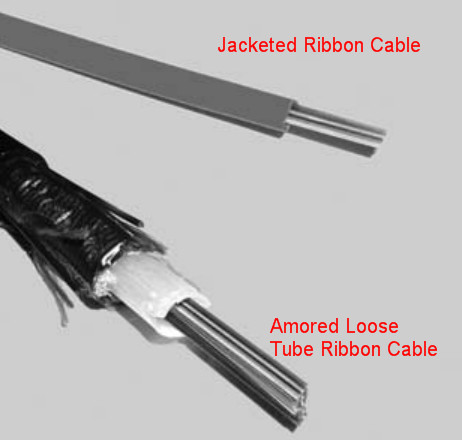

Fiber optic ribbon cable comes in two basic arrangements: Loose tube ribbon cable, fiber ribbons are stacked on top of one another inside a loose-buffered tube. This type of arrangement can hold several hundred fibers in close quaters. The buffer, strength members, and cable jacket carry any strain while the fiber ribbons move freely inside the buffer tube. Jacket ribbon cable looks like a regular tight-buffered cable, but it is enlongated to contain a fiber ribbon. This type of cable typically features a small amount of strength member and a ripcord to tear through the jacket.

Ribbon cables is commonly used in urban construction of circle trank cable network, the large capacity and multi-core features facilitate the jumper box crossing task in the local optical area network. Ribbon cables is rarely used in inter-provincial long distance fiber optic trunk cable.

Ribbon fiber provides definite size and weight saving, which required the connector, strippers, cleavers, and fusion splicers to be tailored to the ribbon fiber. Below is the simple steps of ribbon fusion splicing:

Ribbon fusion splicer is also called mass fusion splicers, it can splice the entire cable ribbons at on time. Ribbon splicers looks similar to single fiber splicers and work in much the same way, except the ribbons are treated as one assembly, stripped, cleaved and spliced by special tools while held in a special holder. The holder is inserted in a special stripper that uses heat to make stripping easier. After stripping, the holder is placed in a special cleaver that will cleave all 12 fibers at once. Then the fixure with all the cleaved fibers is placed in the splicing machine. When the second ribbon is prepared, the unit is set for automated splicing.

Ribbon fusion splicer is also called mass fusion splicers, it can splice the entire cable ribbons at on time. Ribbon splicers looks similar to single fiber splicers and work in much the same way, except the ribbons are treated as one assembly, stripped, cleaved and spliced by special tools while held in a special holder. The holder is inserted in a special stripper that uses heat to make stripping easier. After stripping, the holder is placed in a special cleaver that will cleave all 12 fibers at once. Then the fixure with all the cleaved fibers is placed in the splicing machine. When the second ribbon is prepared, the unit is set for automated splicing.

FiberStore, as one of the main fibre optic cable manufacturers provides a compact, efficient, and versatile solution to applications requiring maximum connectivity in a minimum amount of space. Our ribbon cable assemblies provide up to 72 fiber connections in a single point, reducing the physical space and labor requirement, while providing the same bandwidth capacity of a multi-fiber cable with individual fiber/connector terminations per fiber. The advantage of ultilizing ribbon fiber cables resides in the ability to achieve a much higher density in patch panel, cable routing/ducting, and device connection environments, without compromising the quality or quantity of the connection.